Products list

Contact Us

Address:No.68 Shunhe Road, Jiaoxi, Zhenglu Town, Changzhou City, Jiangsu,China 213116

General manager:Luwenguang 13906123780

Deputy general sales:Chayongqiang 13775013377

Tel:0519-88908088 {zzz:tel22}

Foreign trade department:0519-88901088 67892070

Fax:0519-88902649

Website:www.china-yutong.com

Email:yutong@china-yutong.com

Fluidized bed dryer

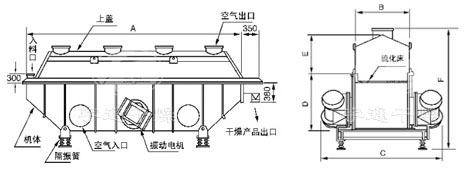

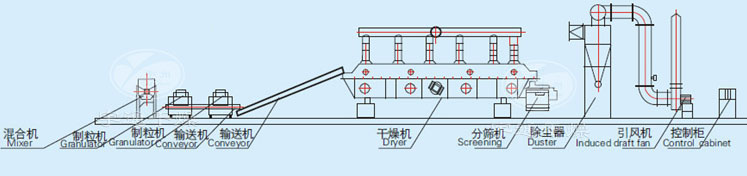

ZDG series vibration fluidized bed dryer

Detailed description

model | Fluidized bed area m2 | Inlet temperature ℃ | The air temperature ℃ | Moisture evaporation capacity Kg / h | Vibration motor | |

model | power | |||||

ZDG3 × 0.3 | 0.9 | 70-140 | 40-70 | 20 to 35 | YZS10-6 | 0.75×2 |

ZDG4.5 × 0.3 | 1.35 | 70-140 | 40-70 | 35 to 50 | YZS10-6 | 0.75×2 |

ZDG4.5 × 0:45 | 2.025 | 70-140 | 40-70 | 50 to 70 | YZS10-6 | 1.1×2 |

ZDG4.5 × 0.6 | 2.7 | 70-140 | 40-70 | 70 to 90 | YZS10-6 | 1.1×2 |

ZDG6 × 0:45 | 2.7 | 70-140 | 40-70 | 80 to 100 | YZS10-6 | 1.1×2 |

ZDG6 × 0.60 | 3.6 | 70-140 | 40-70 | 100 to 130 | YZS25-6 | 1.5×2 |

ZDG6 × 0.75 | 4.5 | 70-140 | 40-70 | 120 to 170 | YZS25-6 | 1.5×2 |

ZDG6 × 0.9 | 5.4 | 70-140 | 40-70 | 140 to 170 | YZS30-6 | 2.2×2 |

ZDG7.5 × 0.6 | 4.5 | 70-140 | 40-70 | 130-150 | YZS30-6 | 2.2×2 |

ZDG7.5 × 0.75 | 5.625 | 70-140 | 40-70 | 150 to 180 | YZS40-6 | 3.0×2 |

ZDG7.5 × 0.9 | 6.75 | 70-140 | 40-70 | 160 to 210 | YZS40-6 | 3.0×2 |

ZDG7.5 × 1.2 | 9.0 | 70-140 | 40-70 | 200 to 280 | YZS50-6 | 3.7×2 |

ZDG7.5 × 1.5 | 11.25 | 70-140 | 40-70 | 230 to 330 | YZS50-6 | 3.7×2 |

DG8 × 1.8 | 14.4 | 70-140 | 40-70 | 290 to 420 | YZS75-6 | 5.5×2 |

Material name | Material shape | First Moisture (%) | Final moisture (%) | Bed capacity (Kg / M2.h) |

Citric acid | granular | 2.5 | 0.5 | 200 |

MSG | Powdery | 5 | 0.3 | 200 |

MSG | granular | 5 | 0.2 | 280 |

Amine stream | granular | 3.01 | 0.28 | 700 |

Stretch acid | granular | 4.1 | 0.3 | 900 |

Sebacic acid | Needle-like crystals | 9.25 | 0.15 | 180 |

Stretch yarn | granular | 6.5 | 0.2 | 500 |

Cellulose (CMC) | Flocculent | 35 | 3.6 | 80 |

NPK | Globular | 24.4 | 5.5 | 280 |

White carbon black | Cream | 78.6 | 11.8 | 100 |

oxalic acid | granular | 6.2 | 0.1 | 700 |

Plastic particles | granular | 3.7 | 0.01 | 300 |

Chinese Herbal Medicine | Sheet | 58 | 4 | 40 |

potassium permanganate | granular | 3.7 | 0.15 | 500 |

aspirin | Powdery | 3.1 | 0.1 | 600 |

FCMP | granular | 11.1 | 0.35 | 400 |

beans | Sheet | 16.8 | 12.5 | 1000 |

Bentonite | Powdery | 20.5 | 0.5 | 500 |

Soybean | Pellets | 12.2 | 10.9 | 1200 |

Activated clay | Powdery | 43.7 | 17.9 | 180 |

Corn germ | granular | 55 | 5 | 50 |

Watercress | Sheet | 18.9 | 13 | 1100 |

Matchstick | Strip | 46.9 | 8 | 100 |

tea | Strip | 15 | 7.4 | 300 |

alcohol | granular | 74 | 8.2 | 50 |

Stem wire | Filamentary | 30 | 14 | 200 |

feed | Strip | 28 | 6.9 | 150 |

Pearl powder | Powdery | 9.1 | 0 | 450 |

washing powder | Powdery | 10 | 1.75 | 300 |

catalyst | granular | 25.5 | 2.3 | 100-300 |

Salt | granular | 1.85 | 0 | 2400 |

Polyethylene | Powdery | twenty one | 0.06 | 120 |

PVC | Powdery | 12.8 | 0.29 | 150 |

starch | Powdery | 43.4 | 13.2 | 90 |

Chicken | granular | 5-7 | 0.5 | 190 |

Ammonium chloride | granular | 4-6.7 | 0.5 | 500-600 |

Prev:XFG closed cycle series boiling dryer

Next:没有下一篇

Scan QR code

Scan QR code