Products list

Contact Us

Jiangsu Yutong Drying Engineering Co. Ltd.

Address:No.68 Shunhe Road, Jiaoxi, Zhenglu Town, Changzhou City, Jiangsu,China 213116

General manager:Luwenguang 13906123780

Deputy general sales:Chayongqiang 13775013377

Tel:0519-88908088 {zzz:tel22}

Foreign trade department:0519-88901088 67892070

Fax:0519-88902649

Website:www.china-yutong.com

Email:yutong@china-yutong.com

Address:No.68 Shunhe Road, Jiaoxi, Zhenglu Town, Changzhou City, Jiangsu,China 213116

General manager:Luwenguang 13906123780

Deputy general sales:Chayongqiang 13775013377

Tel:0519-88908088 {zzz:tel22}

Foreign trade department:0519-88901088 67892070

Fax:0519-88902649

Website:www.china-yutong.com

Email:yutong@china-yutong.com

Vacuum and conduction drying series

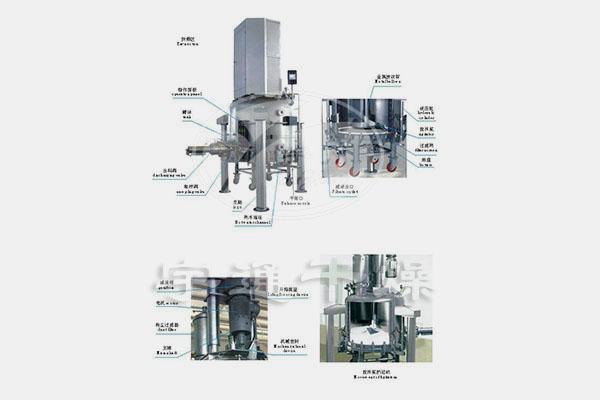

GXG series filter elution drying machine

Profile:This equipment set filtration, beating, washing and drying operations in one, is the ideal equipment for medicine, pesticide, food, chemicals, dyes and other industrial sectors of solid-liquid separation.

Related engineering:

National advisory hotline:13906123780

Detailed description

product description:

GXG series filter elution one machine for drying various materials have good adaptability, especially for difficult to filter slurry and explosive, volatile, easy to deal with pollution and other materials. The equipment set filtration, beating, washing and drying operations in one, is the ideal equipment for medicine, pesticide, food, chemicals, dyes and other industrial sectors of solid-liquid separation.

The machine consists designed by our own development and production, and put to practical use, such products to fill gaps in the domestic, has been widely used in the separation of many harmful contamination of other materials.

Structure description:

GXG series filter elution drying machine is mainly composed of transmission components, to enhance the main components parts, washing parts, scraper, cylinder components, pneumatic device, filter plates, racks and associated piping and measurement and control instruments and other components.

1, the transmission member:

Transmission parts mainly consists of motor, reducer, drive shaft, bearing, lubrication systems, seals and other components. Motor reducer drive shaft and the shaft of the doctor means to achieve positive, reverse, by scraper forward and reverse reach removable cake, grind together the cake cracks caused by pressure leaks, the need for slurry washing material , but also from the mixing effect. Seal ensure no leakage between the cylinder and the shaft to ensure that the cylinder internal pressure.

2, upgrade components:

Lifting member mainly composed of a cylinder, the guide mechanism and other components, is to ensure that the actuator blade up and down movement. Accurate component position to enhance the reliability is crucial, therefore, installation, commissioning, operation and maintenance, it is necessary to adjust well to ensure a good position limit switch to ensure accurate operation of the lift member, because of its position in order to avoid errors , resulting in damage to the blade filter discs and other serious consequences.

3, washing parts:

Washing of the interior of the cylinder member realize washing and cake. Wash liquid from the wash tube entrance, through a plurality of wash nozzles, and the filter cake on the interior of the cylinder to achieve multiple, comprehensive, continuous and uniform washing.

4, the barrel:

The barrel from the cylinder, head assembly, flanges and other components. Head assembly includes a head, breathing valve, safety valve, pressure gauge, sight glass, washing liquid inlet, feed inlet compressed air inlet entrances takeover. Transmission parts, upgrade parts and components are all mounted on the washing on the barrel.

5, scraper:

Scraper achieve three functions:

(1) Discharge: After the filter cake formed on the filter plate, scraper drop and rotate the filter cake and blowing arrived discharge valve from the plane; (2) Flattening: cracks in the cake , the reverse rotation of the blade means, will crack rolled out to avoid pressure leaks, to ensure the normal filtering; (3) mixing: the need for re-slurried filter material, can play a role in stirring and mixing, and to accelerate the washing liquid the mother liquor substitution, optimized washing effect.

6, outlet valve:

Manual or automatic quick opening discharge valve. Mounted on the cylinder side of the cake discharge from the valve port.

7, filter discs:

A plurality of layers sintered metal mesh. It can be divided into integral mount and split-mount. Integrally mounted filter disc as a whole. Split-mounted filter disc is divided into a plurality of blocks each small filter disks installed separately. Can be selected according to actual needs and accuracy of its filter material. Filter plate rigidity, filtration precision, can be repeatedly washed, long-term use. The discs are key components of the entire machine, which is directly related to the precision of the filtering effect.

8, under the barrel:

Under the barrel is installed filter disc carrier. Flange, cylinder, head, discharge valve port, a liquid outlet, movable support frame and the like. Under the cylinder barrel can be in the role of automatically hanging to the ground, through the movable support frame can be quick and easy to move, easy to filter discs do a thorough cleaning.

9, the rack:

Rack entire machine is supported. Rack legs have bolt holes.

10, automatic control system:

Control of the machine through PLC or computer centralized control, through pressure controller, temperature controller, limit switches, proximity switches and level detectors, monitoring and feedback, in order to achieve automatic control.

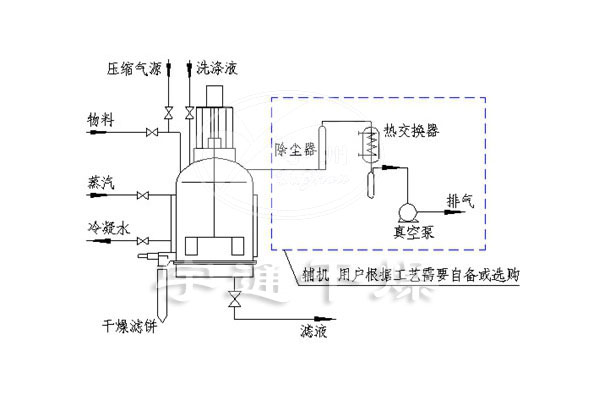

working principle:

GXG series filter elution drying machine working process can be divided into four processes:

(1) feed filtering: under the action of the pump, the material to be separated into the machine through the pump pressure, the initial start filtering. After the feed through into the compressed gas, under the pressure of the compressed air, filtered again, solid-liquid separation of the material to be separated. The filter media according to different products and material properties, the choice of a variety of multi-layered cloth or stainless steel sizes and different media sintered filter disk, filtration precision can reach 5-10μm, filter plate fixed to the machine under the barrel can be cleaned Removable. Replacement of product varieties, only need to replace the filter plates can be realized, a device can be used for multiple products. The filter cake is formed through a special scraper smooth, eliminate cracks in the cake, making cake evenly distributed, uniform thickness, solid-liquid separation is more thorough.

(2) washing beating: can the cleaning liquid through a special body wash round, evenly distributed inside the machine, cleaning and washing materials inside the machine can be achieved. By stirring and mixing action of the scraper can be thoroughly mixed layer by layer, and the filter cake was washed, and finally form a slurry suspension, the filter cake be washed. According to the specific circumstances of the material, you can select multiple washing.

(3) drying: After thoroughly washed, pass into the air, on the cake was dry. The material to be dried, through steam or hot air (nitrogen), under the action of the vacuum, the material dried.

(4) Discharge: to be dry cake under the action of the scraper cake was blowing and was rushed to the side of the discharge valve, from the plane.

Features:

1, multi-service, including filtration, elution and a drying machine function;

2, operating in a closed environment, especially for hazardous substances, contaminated materials should be avoided.

3, can be PLC control, high degree of automation

4, double mesh strainer to ensure that no material leakage.

5, compact, easy to install, operate and maintain, take place.

6, no vibration and noise, stable and reliable.

7, the device can be made of stainless steel, easy to clean, fully determined GMP standards.

Applications:

1, the pharmaceutical industry.

2, fine chemicals.

3, dyes and pigments industry.

4, the food industry.

5, agricultural products refined chemicals.

6, polymers and resins.

7. The device can be made of stainless steel, easy to clean, fully determined GMP standards.

Technical Parameters:

|

Model |

Mm inner diameter of the container |

M filter area |

Nominal volume m3 |

Cake thickness mm |

Nominal pressure MPa |

Power Kw |

|

GXG600-N |

f600 |

0.25 |

0.2 |

≤200 |

0.6 |

2.2 |

|

GXG800-N |

f800 |

0.5 |

0.5 |

≤200 |

0.6 |

4.0 |

|

GXG1000-N |

f1000 |

0.75 |

0.8 |

≤300 |

0.6 |

5.5 |

|

GXG1200-N |

f1200 |

1.0 |

1.0 |

≤300 |

0.6 |

7.5 |

|

GXG1400-N |

f1400 |

1.5 |

1.6 |

≤400 |

0.6 |

7.5 |

|

GXG1600-N |

f1600 |

2.0 |

2.4 |

≤400 |

0.6 |

11.0 |

|

GXG2000-N |

f2000 |

3.0 |

4.5 |

≤500 |

0.5 |

15.0 |

|

GXG2400-N |

f2400 |

4.5 |

6.0 |

≤500 |

0.5 |

18.5 |

|

GXG2800-N |

f2800 |

6.0 |

7.0 |

≤500 |

0.5 |

18.5 |

|

GXG3000-N |

f3000 |

7.0 |

10.0 |

≤500 |

0.4 |

22.0 |

|

GXG3200-N |

f3200 |

8.0 |

12.0 |

≤500 |

0.4 |

22.0 |

|

GXG3500-N |

f3500 |

9.5 |

15.0 |

≤500 |

0.4 |

30.0 |

Note: You can select different filter precision machine materials, structural configuration, etc. depending on the material.

Flow chart:

Scan QR code

Scan QR code