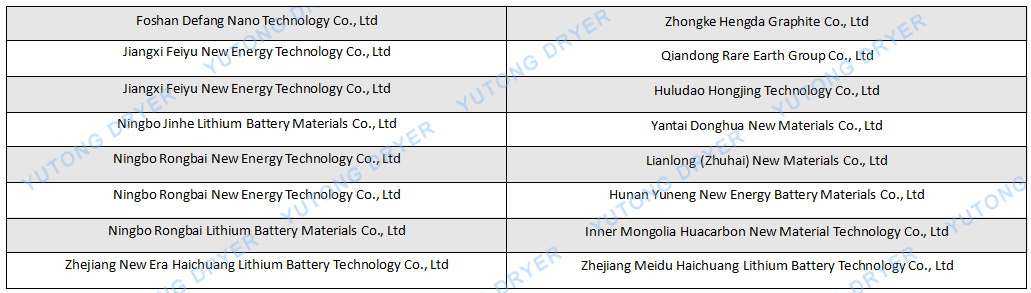

Hubei Rongbai New materials, Ningbo Jinhe new materials, Zhejiang Meduhai innovative materials, Hunan Shanshan, Xiamen Tungsten Industry

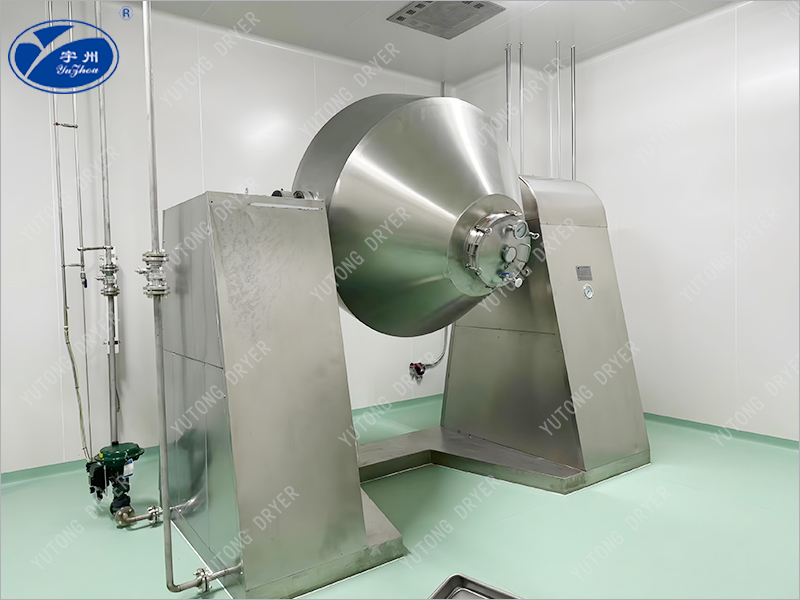

The equipment is suitable for ternary materials, lithium iron phosphate and other materials with very low final moisture requirements.

The unit is based on the old process of lithium battery double cone dryer, improved and upgraded, according to the condition of lithium battery materials customized automatic double cone unit, from the feed to the finished product discharge can achieve one-click automation, continuous production, in ensuring product quality while reducing manual strength greatly improve production capacity.

In addition to the main double-cone rotary vacuum dryer, the unit also includes automatic feed docking device, mold temperature machine high temperature oil heating system, vacuum filter condensation recovery system, discharge automatic docking device, spiral belt cooling machine. After the upper centrifuge or filter press completes the work, the feed device of the double cone dryer will automatically butt to add the materials to the double cone dryer, and then the vacuum system and the die temperature machine system will automatically run for drying. After the preset time, the automatic discharge device will automatically butt to put the dried materials in the double cone into the spiral belt cooling machine to cool down. After cooling to the preset time, it can be interlocked with the rear pneumatic conveying system and directly stored in the finished product silo.

1, the double cone internal smooth transition, small wear, and spray tungsten carbide or titanium to prevent metal ions exceed the standard.

2, high temperature heat conduction oil heating, high vacuum to ensure the final moisture of the product.

3, reduce manual operation, prevent high temperature burns, reduce artificial strength.

4, continuous production, greatly improve production capacity.

5, save energy, the dryer does not need to heat drying, cooling discharge repeated operation, can always be maintained in a high temperature state.

Previous :none!