Our company developed and produced GXCX type high-efficiency chromatographic column, which is a high-efficiency chromatographic device using medium-pressure axial linear flow technology. The equipment has 0.5 type 600 series specifications 10 varieties, with the advantages of fast separation speed, short working time, high purification efficiency, easy operation and use, and wide application range. It is used in difficult to separate materials, can improve work efficiency, and has been widely used in chemical, food, pharmaceutical (traditional Chinese medicine, pesticide) natural plants, Marine organisms, biochemical products, genetic engineering and other industries.

In view of our company's technical strength and rich production practical experience, in recent years, combined with the market demand and the user's extraction separation production process status quo, to choose a reasonable technical solution and sophisticated equipment selection, and to ensure high-quality and reliable manufacturing quality. Our company at the same time in tooling technology, testing means and product design and other aspects of continuous improvement and increasingly perfect, has made remarkable gratifying results, technical level and product quality are in the leading level in China.

The GXCX high-efficiency chromatography device consists of main components such as a feed solvent tank, a pressure pump (or nitrogen), a multi-stage switching solenoid valve, a control valve, a controller, a packing (fixed phase) column, and a detector. The key technologies are described as follows:

① liquid tank

The material liquid tank is a specialized container for receiving materials, eluents, and cleaning agents. It is equipped with two types of machines: variable frequency magnetic stirring and non stirring. It has the characteristics of achieving continuous operation and efficient and fast converter function.

② pressure pump

The pressure pump is used for feeding, washing, and cleaning the working liquid of the chromatography column, with the advantages of high working pressure, low flow rate, good stability, and no damage to the active substances and liquid leakage. Therefore, the selection and configuration of the pump are particularly important. Whether it can work normally in the separation process is important to the shape of the pump.

③ Multi-level solenoid valve system

When the material feeding work is completed, the eluant is switched instantly. When turning to the cleaning agent system, the application of manual and automatic two technical forms, to achieve the entire system pipeline connection, switching accurate process purposes, the application of automatic technology, can replace the complicated manual operation, improve work efficiency and reliability, and there is no leakage of solvents, so that the machine is more compact, the work pace is consistent.

④ controller

The control product is the command center of the whole machine. In front of the controller, there is a micro static high efficiency mixer, pre-filter and defroster. In order to ensure the balanced distribution of materials and the effective mixing of eluents, the controller plays a very key role, and the controller also plays an effective role in protecting and regulating the pressure supply of the pressure pump, the flow rate of the solution, and the flow rate.

⑤ Real material (fixed phase) column

The mechanism design of the column, precision manufacturing, reasonable distribution of fluid guidance and accurate calculation of filtration area, as well as the ability to achieve linear flow velocity of high-speed fluid, are key technologies that determine the success of separation. Therefore, our company has gathered international advanced technology to update the design of the column structure, successfully solving the operability of rotating the column 180 °, making it more convenient to feed and unload packing.

⑥ Detector

According to the different process conditions, various detectors can be recommended or selected for users to track and detect the separated substances and record all equipment processes. The following technical features and advantages of high-efficiency chromatography equipment are incomparable to traditional chromatography columns.

1. It is easy to carry out linear amplification on the basis of the original process, improve the production efficiency and shorten the time of production and release to the market.

2. It can be operated with large flow at low linear flow rate to improve production efficiency, and its flow rate can be increased by 5-15 times.

3. Improve the utilization rate of filler, so that the amount of filler per unit volume reaches a high combination amount, which is especially obvious in industrial production.

4. Reduce the separation time, so that the product has high activity and yield, with significant economy;

5. The filling can rotate the cylinder 180°, easy to disassemble and assemble, easy to operate, reduce cross contamination, and meet the process requirements of GMP.

7. Bed height is moderate, ensure that the back is low.

8. Packing (stationary phase) column, no dead volume.

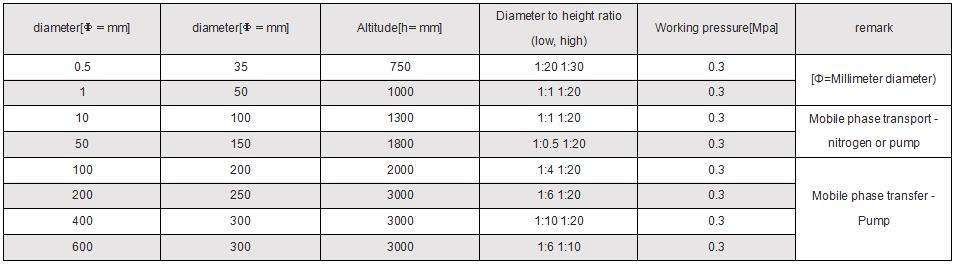

It can realize the operation under the condition of nitrogen pressure and high pressure pump, under normal circumstances,0.5L-10L chromatographic column can be optional with nitrogen pressure, saving investment, more than 50 can use high pressure pump, which can improve the efficiency. According to the actual demand and process conditions, the chromatographic column can be optimized and combined with other supporting equipment to achieve the investment effect.

Note :1. The selection of material according to the process requirements, the use of stainless steel SUS304,SS316L. Or coated nickel phosphorus. 2. Users have special requirements can be separately designed and manufactured.

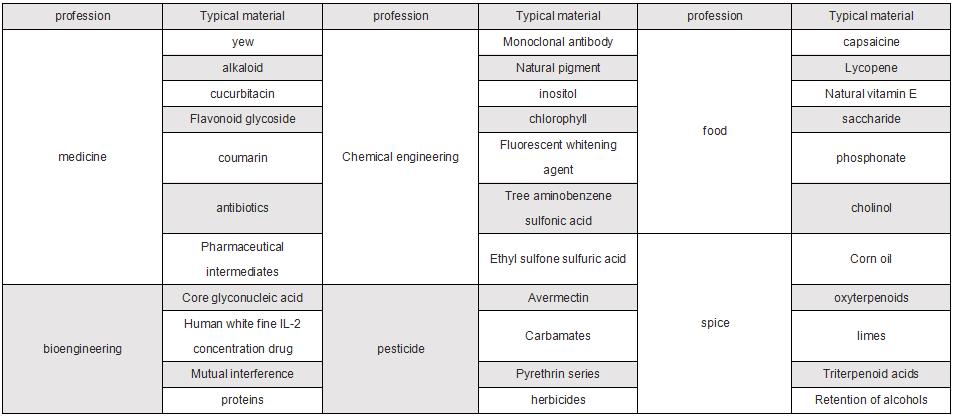

The high-efficiency chromatographic column device is widely used in Chinese and Western medicine, herbal medicine, food, fine chemical industry, natural plants, property Marine biology, biochemical products, genetic engineering and other fields, and has good usability and separation effect. Scope of application See the following table: