The air flow spray drying process can be divided into two types according to the needs of the process. One is the top spray type, that is, the nozzle is set on the top of the drying tower, and the atomized liquid and hot air flow from top to bottom to complete the drying process, which is suitable for drying materials with high viscosity and certain heat sensitivity; The second method is to set the nozzle at the bottom of the drying tower, and the atomized liquid and hot air work together from bottom to top to complete the drying process, which is suitable for drying materials with good temperature resistance. This method was originally used for drying traditional small-scale water reducing agents.

The atomizer of the air flow spray dryer is also called the air flow nozzle. The nozzle structure is generally simple. Low viscosity materials and high viscosity liquid can be atomized. The application range is wide. The particles obtained are fine, generally about 5-30 microns, and the operation flexibility is large. But its disadvantage is also very obvious, that is, the power consumption of compressed air used for atomization is relatively high, mainly used for atomization drying of high viscosity or high molecular weight organic liquids.

Airflow nozzles can be divided into two fluid and three fluid types based on their structure, with the two fluid type further divided into external mixing and internal mixing types.

After being heated by clean air, it enters the drying tower and is transformed into tiny droplets using a two fluid (or three fluid) nozzle in the hot air inside the tower. It undergoes rapid heat exchange with the hot air, evaporates the water (or solvent) in the liquid material, and is discharged with the hot air to obtain powdered products.

1. Especially effective for sticky, paste like, and paste like materials, which cannot be replaced by other equipment.

2. Experimental variety and wide application of low-temperature drying.

3. The nozzle structure is simple, easy to maintain, and has low operating costs.

4. The operating environment is good, and the dust emissions meet the national standard requirements.

5. The dried product has excellent quality, uniform particle size, good flowability, and uniform final moisture content.

Food: amino acids, condiments, protein, milk powder, pig blood powder, soy sauce powder, tea powder, glucose, potassium sorbate, essence and spices.

Pharmaceutical products: vitamins, traditional Chinese medicine, antibiotics, etc.

Chemical products: Disperse dyes, reactive dyes, organic catalysts, white carbon black, laundry detergent, potassium carbonate, potassium phosphate, various waste liquids, etc.

Choose the concentric coaxial atomizer independently designed by Qiao Feng, with customizable nozzle aperture.

Choosing wear-resistant and corrosion-resistant 16 # silicone tubing can meet the transportation needs of most heat sensitive materials.

The feeding device is an embedded peristaltic pump, with precise speed control and safer one-way rotation.

High borosilicate glass drying components with good transparency and acid and alkali resistance.

The clamp of the fixed component is made of high-quality aluminum alloy material, which is tight, durable and has no dead corners.

The cyclone separator and bag filter device can be switched for use, and can screen and collect materials of different particle sizes.

Using oil-free air compressors imported from Taiwan, with low pollution, low noise, and sustainable operation.

Adopting high-precision PID temperature control technology, the temperature control accuracy range is 1 ℃, and the electric heating source is stable and more environmentally friendly.

Intelligent human-machine interactive interface, easy to operate, supports switching between Chinese and English.

The dried finished dry powder has a relatively uniform particle size, with over 95% of the dry powder within the same particle size range.

For viscous materials, a nozzle cleaner (through needle) is installed, which will automatically clear the nozzle when it is blocked, and the frequency of the through needle can be automatically adjusted.

The stainless steel drying chamber can be used for tower wall blowing (optional).

Accepting customization (such as fully equipped imported accessories, sandblasted appearance, designing models according to laboratory environment, etc.)

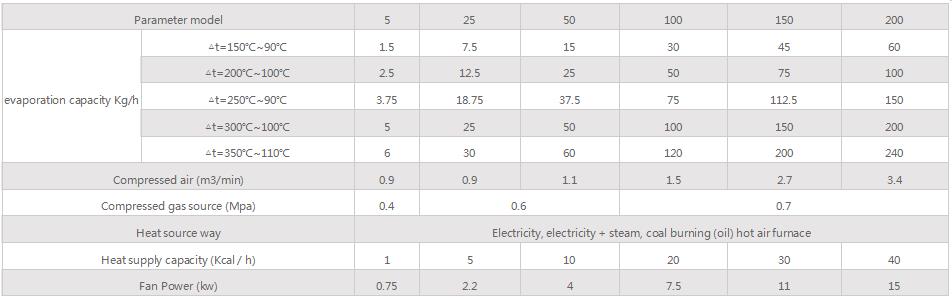

Note:

1. This device can be designed and manufactured according to actual needs for models larger than 200;

2. The fan power is standard configuration, and if bag dust removal and solvent recovery devices are added, they need to be modified accordingly.

Previous :none!