Products list

Contact Us

Address:No.68 Shunhe Road, Jiaoxi, Zhenglu Town, Changzhou City, Jiangsu,China 213116

General manager:Luwenguang 13906123780

Deputy general sales:Chayongqiang 13775013377

Tel:0519-88908088 {zzz:tel22}

Foreign trade department:0519-88901088 67892070

Fax:0519-88902649

Website:www.china-yutong.com

Email:yutong@china-yutong.com

Extracting and concentrating equipment

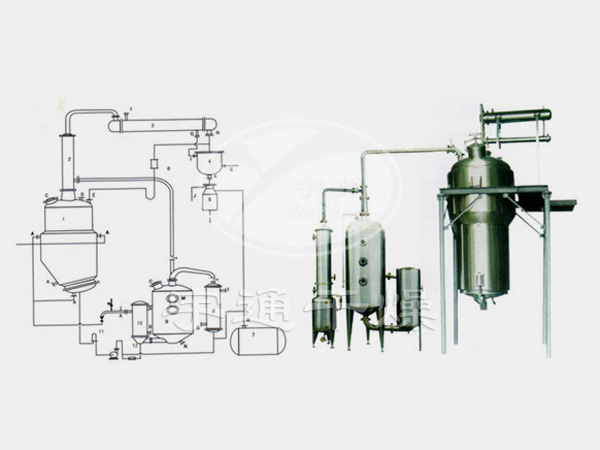

Thermal reflux extraction concentrator

Detailed description

Works

will invest herbs extraction tank, add herbs 5-8 times a solvent (water, ethanol, acetone, etc., according to process requirements). Open the extraction tank through the steam valve and jacket, so that the extract is heated to boiling 20 to 30 minutes later, with a suction tube to extract 1/3 into the concentrator. Close the extraction tank through and jacket steam, open the heater valve to concentrate the liquid material. Concentration generated secondary steam, through the evaporator riser tube into the extraction tank for the extraction of heat and solution to maintain the extraction tank boiling.

The secondary steam continues to rise, the condenser condensing into a hot condensate, back to the extraction tank for new solvents added to the drug surface, the new solvent from top to bottom through the medicine layer to the bottom of the extraction tank, the soluble active ingredients dissolved In a solvent. The extracted liquid is drawn into the concentrator through the filter tube, and the secondary vapor produced by the concentration is sent to the extraction tank as the heat source and the new solvent. The new solvent is recirculated and reclaimed so that the solute density in the medicinal material keeps with the solute density The concentrated solution is continuously transferred to the concentrator and the condensed secondary steam is transferred to the cooler, and the concentration is continued until the ointment having the specific gravity (1.2 to 1.34) is concentrated and released for use . Extraction residue can be put into the tank for the next batch, slag from the slag gate drain, if extracted with organic solvents, the first increase the amount of water, open and jacket steam, recovery of solvent, the Slag discharge row.

Features

1, cream collection rate increased to 15% compared with 10 multi-purpose tanks, ointments containing the active ingredient higher than 1 times. As the extraction process, the hot solvent added to the drug surface continuously, from top to bottom through the drug layer at high speed, dissolve the solute in the medicinal herbs, solute content in the solvent and solvent content to maintain a high gradient, herbs Soluble high-speed dissolution, until completely dissolved, the effective component extraction rate is high, concentrated in a set of sealing equipment to complete, loss of small, high conversion rate, the high rate of cream, ointment high active ingredient content.

2, due to high-speed dissolution of solutes, extraction time is short, concentrated and extraction simultaneously, so the medicine to the concentrated ointment only 7 to 8 hours, equipment utilization.

3, a single device, an area of small, high utilization of equipment, investment province.

4, the extraction of only one solvent, in a set of sealing equipment recycling, solvent residue in the solvent is basically recovered, the amount of solvent than multi-function extraction tank 30% less, consumption rate can be reduced by 50 to 70%, which is With the organic solvent extraction, purification of active ingredients in traditional Chinese medicine to provide a more advanced process methods.

5, due to the concentration of secondary steam for the extraction of heat, extracted into the concentrator with the concentration of the extract and the temperature can save steam, the operation easier, reducing the operator.

Features

The equipment is suitable for herbal plants, herbs, animals, and food additives. The use of water, ethanol, methanol, acetone, such as the extraction and recovery and concentration of organic solvents.

Technical parameters:

extraction tank area: 1m3 2m3 3m3 6m3

concentrator volume: 0.5m3 1m3 1.5m3 2.5m3

water extraction temperature: 90-100 ℃

alcohol extraction temperature: 78-83 ℃

extraction time: 4-5 hours / batch

vacuum: 0.05-0.08MPa

pressure: 0.08-0.2MPa

Scan QR code

Scan QR code