Products list

Contact Us

Address:No.68 Shunhe Road, Jiaoxi, Zhenglu Town, Changzhou City, Jiangsu,China 213116

General manager:Luwenguang 13906123780

Deputy general sales:Chayongqiang 13775013377

Tel:0519-88908088 {zzz:tel22}

Foreign trade department:0519-88901088 67892070

Fax:0519-88902649

Website:www.china-yutong.com

Email:yutong@china-yutong.com

conductive drying series

CT-C series hot air circulation oven

Detailed description

First, the heat source has steam, electricity, far infrared, electric steam dual-use for users to choose.

Second, the use of temperature: steam heating 50-140 ℃, maximum 150 ℃.

Third, electricity, far infrared temperature of 50-500 ℃.

Fourth, with automatic and computer control systems for customer choice.

Five commonly used steam pressure 0.02-0.8Mpa (0.2-8kg / cm).

Six, with electric heating, calculated according to I-15KW, practical 5-8kw / h.

Seven special requirements when ordering instructions.

Eight non-standard oven price is negotiable.

Nine, temperature greater than 140 ℃ or less than 60 ℃, to specify when ordering.

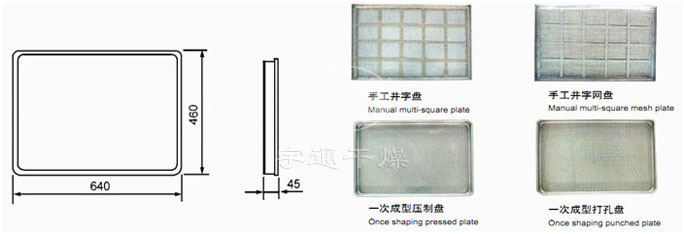

Ten, factory car factory bake, baking tray size uniform, interchangeable.

XI, baking tray size: 460 × 640 × 45mm.

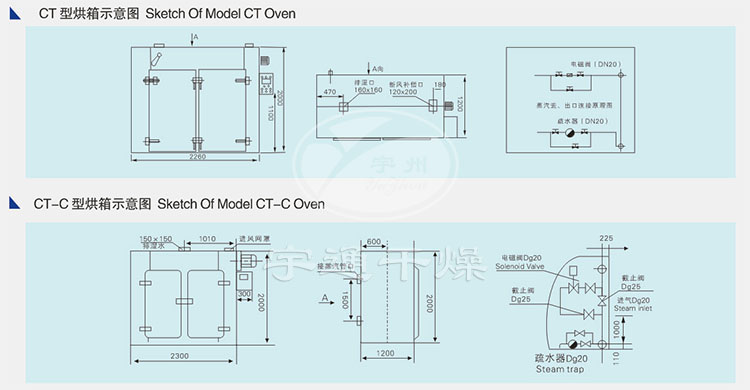

CT-CO schematic model oven

|

model |

YY |

Technical Parameters |

Fitting |

Total |

|||||||||||

|

Steam |

There are |

Each |

San |

Consumption |

Electricity |

Wind |

Wind |

Inside temperature difference (° C) |

Outer |

Should be equipped with drying cars (vehicles) |

Shall be |

Temperature-controlled box |

|||

|

CT-I |

RXH- |

14.1 |

2.6 |

120 |

twenty three |

20 |

15 |

1414 |

1.1 |

±2 |

2480x |

2 |

48 |

no |

1220 |

|

CT-Ⅱ |

RXH- |

28.3 |

4.9 |

240 |

48 |

40 |

30 |

5230 |

1.1 |

±2 |

2480x |

4 |

96 |

no |

1530 |

|

CT-Ⅲ |

RXH- |

42.4 |

7.4 |

360 |

72 |

60 |

45 |

9800 |

2.2 |

±2 |

3430x |

6 |

144 |

no |

2110 |

|

CT-Ⅳ |

RXH- |

56.5 |

10.3 |

480 |

96 |

80 |

60 |

9800 |

2.2 |

±2 |

4460x |

8 |

192 |

no |

2300 |

|

Cl-CO |

RXH |

4.8 |

0.85 |

25 |

5 |

5 |

6 |

3450 |

0.45 |

±2 |

1400x |

1 |

16 |

Have |

680 |

|

Cl-C-IA |

RXH |

7.1 |

1.3 |

60 |

10 |

10 |

9 |

3450 |

0.45 |

±1 |

1400x |

1 |

twenty four |

Have |

820 |

|

Cl-C-I |

RXH |

14.1 |

2.6 |

120 |

20 |

18 |

15 |

3450 |

0.45 |

±2 |

2300x |

2 |

48 |

Have |

1580 |

|

Cl-C-Ⅱ |

RXH |

28.3 |

4.9 |

240 |

40 |

36 |

30 |

6900 |

0.45x2 |

±2 |

2300x |

4 |

96 |

Have |

1800 |

|

Cl-C-ⅡA |

RXH |

28.3 |

4.9 |

240 |

40 |

36 |

30 |

6900 |

0.45x2 |

±2 |

4460x |

4 |

96 |

Have |

1880 |

|

Cl-C-Ⅲ |

RXH |

42.4 |

7.4 |

360 |

80 |

54 |

45 |

10350 |

0.45x3 |

±2 |

3400x |

6 |

144 |

Have |

2210 |

|

Cl-C-ⅢA |

RXH |

42.4 |

7.4 |

360 |

80 |

54 |

45 |

10350 |

0.45x3 |

±2 |

2300x |

6 |

144 |

Have |

2100 |

|

Cl-C-Ⅳ |

RXH |

56.5 |

10.3 |

480 |

100 |

72 |

60 |

13800 |

0.45x4 |

±2 |

4460x |

8 |

192 |

Have |

2800 |

Studio Size: any size according to user requirements design;

Temperature parameters: according to user desired temperature range, the temperature uniformity of design and other technical indicators;Type of construction: monolithic, Assembled;

Type of heating: electric heating, fuel, gas heating, steam heating, heating the mixture;

Hot air circulation: Depending on the baked product different place, elective reasonable hot air circulation (as Robin blast side, top blowing double loop before and after the big blast circulation and the like;

Open the door: front door, front door, a top door, lift gate;

Workpiece feed mode: Car-roll row type, plate chain, mesh belt, pusher;

Trolley drive: human type, cogwheel pin rack drive, drive tractors, vol Yang drive, the drive roller row;

Temperature control: Bit digital display instrument temperature control, time proportional temperature controller temperature control domestic intelligence (procedures) imported intelligent temperature controller temperature control (program) temperature controller temperature control.

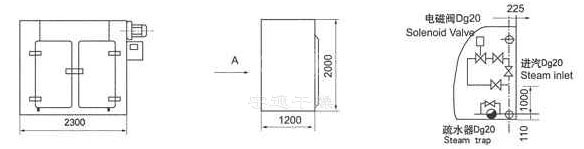

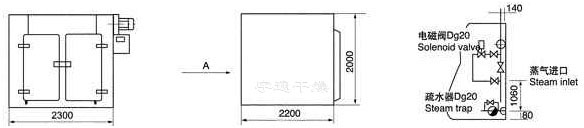

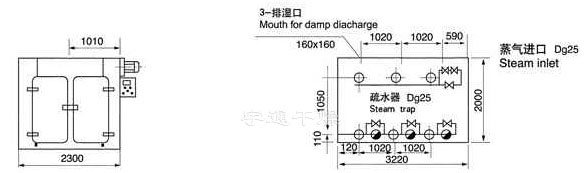

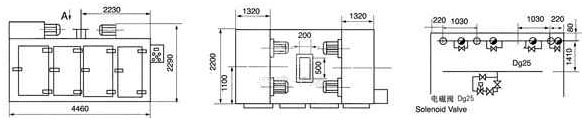

Schematic:

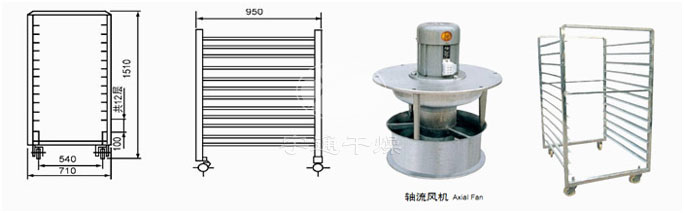

air exchanger:

Stereotypes drying cars:

Material: Stainless steel, A3 steel

Material: Stainless steel, rust-proof aluminum.

Ordering Information:

◆ heating source of steam, electricity, far infrared, electric steam dual-use;

◆ commonly used steam pressure: 0.02-0.8Mpa (0.2-8kg / cm2)

◆ equipped with electric heating: 15kw (according to CT-C-1 computing), practical 5-8kw / h;

◆ Operating temperature: steam heating 50-140 ℃, maximum 150 ℃; electricity, far infrared 50-350 ℃;

◆ equipped with automatic control system and computer control system for users to choose;

◆ Our factory baking car, baking tray size uniform, interchangeable;

◆ temperature greater than 140 ℃ or less than 60 ℃, when ordering requirements;

◆ special requirements should be indicated when ordering.

Prev:SG series of hot air tunnel oven

Next:没有下一篇

Scan QR code

Scan QR code